Semiconductor manufacturing’s return to the U.S. is a hot topic in light of policy actions such as the national CHIPS and Science Act and Arizona’s New Economy Initiative, which is bringing advanced technology jobs and manufacturing to Arizona. Along with these policies designed to spur domestic production of microelectronics, the U.S. Defense Advanced Research Projects Agency, or DARPA, is turning an eye to future needs.

DARPA launched the Next-Generation Microelectronics Manufacturing, or NGMM, program to develop systems to build new technology known as three-dimensional heterogeneously integrated, or 3DHI, microelectronics in the U.S. 3DHI microelectronics use a new architecture that can improve chip efficiency compared to current 2D and 3D designs. The program is part of DARPA’s larger Electronics Resurgence Initiative 2.0, which aims to make the U.S. a world leader in microelectronics.

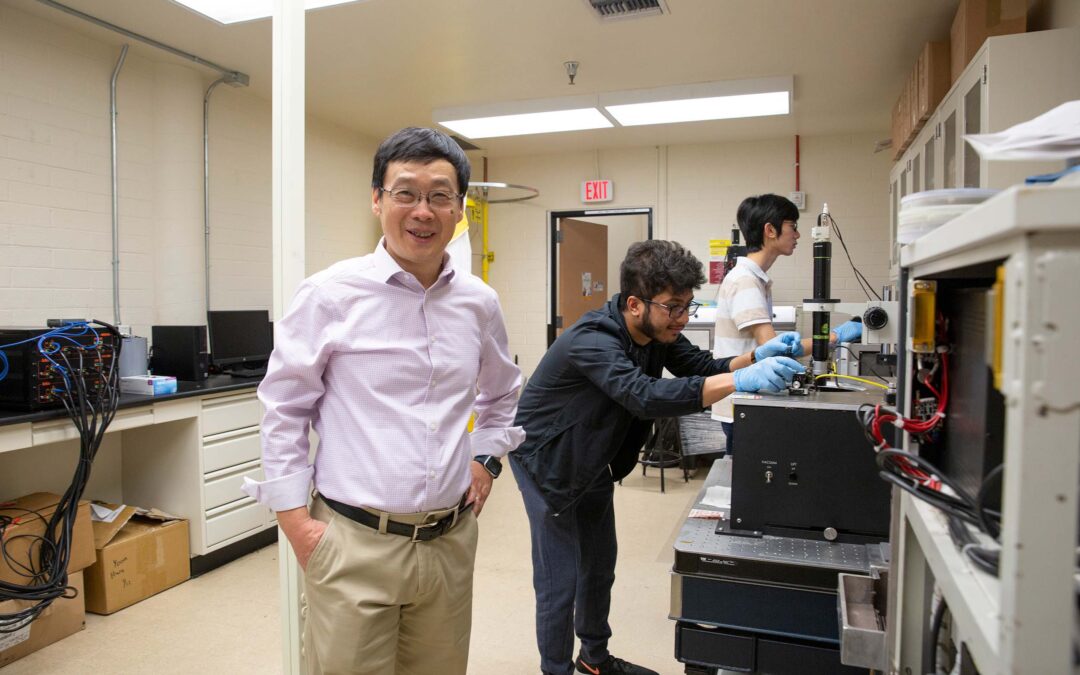

Hongbin Yu, a professor of electrical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, leads a team funded by a $1.5 million grant through Phase 0 of the NGMM program — a six-month process in which researchers analyze manufacturing methods and turn their findings into recommendations known as exemplar microsystems. The recommendations aim to find the best way to create both a production facility and explore best practices for developing these microsystems.

“We’re thinking about how we can make the electrical connections reliable and cost-effective,” says Yu, a faculty member in the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools. “We’re also looking at aspects of how to simplify the manufacturing process. We have to do it cheaply; if you spend $1 billion to make one 3DHI microsystem device, that doesn’t work.”