ASU’s School of Electrical, Computer and Energy Engineering undergraduate spring Class of 2024 demonstrated the capstone group projects they created during their senior year

After years of learning a variety of skills in the electrical engineering undergraduate program in the Ira A. Fulton Schools of Engineering at Arizona State University, students face one final test before graduation: They must show off their ability to solve a real-world problem using their knowledge. To put the skills they’ve learned to task, students coordinate a capstone group project incorporating electrical engineering.

Forty-eight teams from the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools, presented their projects at the Spring 2024 ECEE Senior Design Capstone Demo Day. The students developed solutions to electrical engineering problems in a variety of fields, including assisting those with visual disabilities and automating a greenhouse and solar panel cleaning.

Fulton Schools faculty led some of the projects, while industry mentors oversaw others to fulfill needs with fresh solutions from the latest crop of budding electrical engineers.

A screen reader for real life

Electrical engineering capstone project team members pose behind a table displaying their interactive visual assistant. The technology interprets objects and provides an audio description for those with visual disabilities. Photographer: TJ Triolo/ASU

One of the capstone teams developed a project they dubbed an interactive visual assistant. The system uses a camera to “see” items in real life, then provides a computer-generated audio description spoken to the user describing what’s in front of them.

The project is intended to assist those with visual impairments, working similarly to a screen reader on a computer for physical objects. It uses a Raspberry Pi chip programmed for the purpose connected to artificial intelligence, or AI, large language models such as ChatGPT, which serve as knowledge databases to interpret objects the camera observes.

Ahmed Alkhateeb, a Fulton Schools assistant professor of electrical engineering, served as the project’s mentor. For the students involved, creating the system was a learning experience in a variety of skills, including project management, delegation and ensuring the final product met a stakeholder’s criteria.

“We’ve been having issues with getting the Raspberry Pi to work consistently, specifically with the camera and the microphone aspects of it,” says team member Antonia Scott. “Those two have been giving us some finicky issues that we’ve had to go down massive debug routes for, and that was definitely a frustrating experience, but we learned a lot through it.”

Team member Kaira Monson concurs the learning experience was valuable, especially as it relates to AI for electrical engineering.

“I think it looks good to be able to say you did this project, especially if you’re interested in AI fields, since ours is very AI-heavy,” Monson says.

A greenhouse for growing vegetables on Mars

An electrical engineering capstone team poses with their automated greenhouse project. The greenhouse uses artificial intelligence to control parameters to optimize plant growth. Photographer: TJ Triolo/ASU

Another project used AI for a different purpose: automating a greenhouse’s functions. Sponsored by Astro Seed, a company creating greenhouse technology to grow plants in environments on Earth and extraterrestrial worlds, the team built a small-scale prototype of a greenhouse with automated care functions for two plant compartments.

Housed in a small 3D printed structure, the miniature greenhouse uses sensors for temperature, moisture and environmental control. The sensors send data to an Arduino chip, which uses AI to analyze the parameters supplied and adjust plant growth technology such as water pumps and LED lights accordingly.

Originally, the capstone project was supposed to have nine plant compartments. However, as the project went on, the team realized they’d have to scale back their design to contain two due to resource constraints such as the lengthy printing time for the structure’s complex design.

Group member Yasmin Estrada says pivoting on the project’s scope and size was one of the biggest challenges.

“We had to change our scope multiple times to be able to build this prototype,” Estrada says.

Team member David Lampert says as the project progressed, it became a learning experience about how to work with a customer to ensure Astro Seed’s needs were met.

“We learned a lot about relationship management and communication,” Lampert says.

Improving solar panel efficiency through automated cleaning

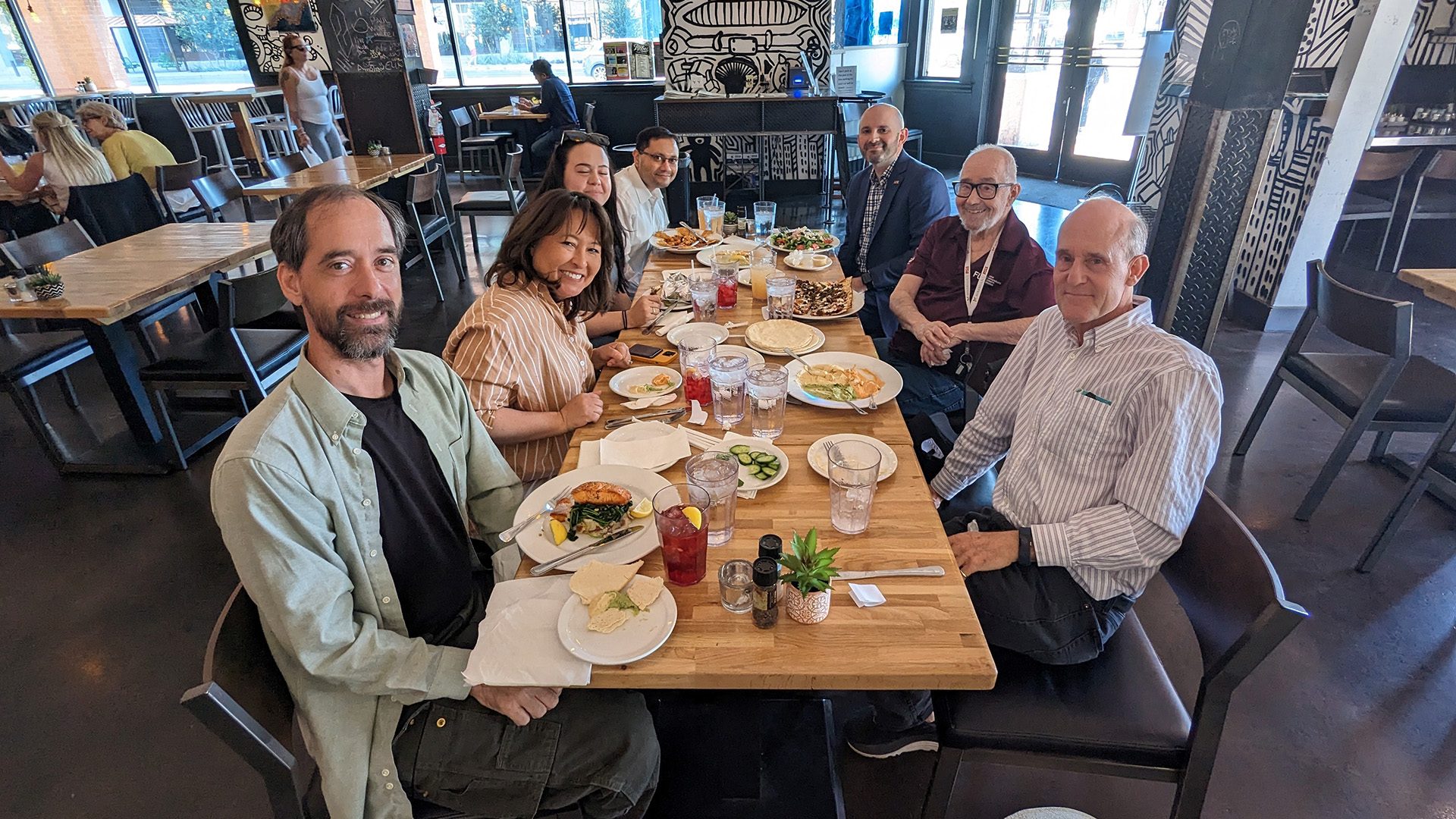

The Palais Senior Design Prize-winning team celebrates their victory at a lunch with team mentor Anamitra Pal (fourth from left), an associate professor of electrical engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, award namesake Joseph Palais (second from right), a professor emeritus of electrical engineering in the Fulton Schools, and Stephen Phillips (right), director of the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools, and a Fulton Schools professor of electrical engineering. Photo courtesy of Anamitra Pal

As automation becomes more prevalent, one team used it for a different direction than computer-controlled greenhouse operation. Under the mentorship of Anamitra Pal, a Fulton Schools associate professor of electrical engineering, student members designed a robot programmed to clean roof-mounted solar panels.

A drone controlled by a human operator picks the robot up from the ground, carries it to the solar panel and drops it off. The robot’s programming sequence then begins, and it removes dirt and debris from the panel, ensuring maximum efficiency to harness the sun’s energy.

The drone is then flown back onto the roof and retrieves the cleaning robot once it’s finished.

The team’s innovative project received the Palais Senior Design Prize. The winning project is selected through judging from a secret panel of attendees at Demo Day and receives a cash prize and a lunch with Professor Emeritus Joseph Palais, who sponsors the prize with his wife Sandra Palais.

“Through the long nights and obstacles that were thrown to the team, winning the Palais Award is an accomplishment,” says team member Sladjana “DJ” Opacic. “It validates our efforts put into the project, and no matter what, it tells us not to give up because maybe someday, our prototype will have a significant impact to society.”

Team member Noah Crowe says the project taught the group to consider all angles and potential issues in an engineering project.

“There is more than meets the eye when building a product from an idea,” Crowe says. “Vital problems such as finding ways to ensure electrical continuity between moving parts can easily be overlooked early in a project.”